These laboratories, primarily located in the Calloway building at Georgia Tech offer a comprehensive capability for both the characterization and reliability of Flexible Wearable Electronics. Flexible Wearable Electronic components and systems can be both mechanically and thermally stressed as needed to determine the robustness of technology.

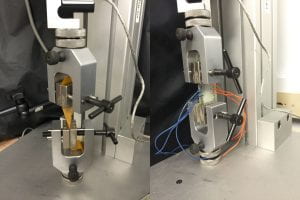

Mechanical testing initially focuses on bending, stretching, and twisting flexible wearable electronic components and systems. During such mechanical testing under monotonic as well as cyclic loading conditions, changes in various mechanical, electrical, and thermal properties will be determined. Also, failure strength and the number of cycles to failure will be assessed. In addition, adhesion strength and interfacial fracture of printed and assembled components will be studied. Vibration and shock/impact studies are planned and implemented in the future. Besides, mechanical tests, facilities for thermal cycling, temp/humidity bias, long-term thermal storage, etc. are also available.

Mechanical Stress Reliability Contact: Suresh K. Sitaraman – Morris M. Bryan, Jr. Professor in CAE and Design

suresh.sitaraman@me.gatech.edu

Thermal Cycling, Temp/Humid/HAST Contact: Christopher White